UF flat sheet

The selection of ultrafiltration flat sheet membranes from Alfa Laval covers a broad spectrum of flux properties and molecular weight cut-off values. The membranes are used in an extensive range of processes applied in the food, beverage, dairy, biotech and pharmaceutical industries

Alfa Laval offers a wide range of flat sheet membranes for ultrafiltration (UF) with different flux properties, molecular weight cut-off values and rejection capabilities. The membranes are made of different polymer types based on a unique construction of either polypropylene (PP) or polyester (PET) support material which provides optimum cleaning conditions.

FS, RC and ETNA types

This series of Alfa Laval flat sheet membranes for ultrafiltration covers the membrane types FS40PP, RC100PE, RC10PE, RC70PP, ETNA10PP and ETNA01PP.

- The FS membrane is made of fluoro polymer and has a MWCO value of 100,000.

- The RC membrane is made of regenerated cellulose acetate with MWCO values up to 100,000.

- The ETNA membrane types are made of composite fluoro polymer with MWCO values of either 1,000 or 10,000.

UF-pHt™ types

In this series of Alfa Laval flat sheet membranes for ultrafiltration you will find the GR40PP, GR60PP, GR61PP, GR70PP, GR80PP, GR90PP and GR95PP types. As the name of the type indicates, these membrane types are all characterized by their tolerance to high pH values and high temperatures.

- The GR40PP, GR60PP, GR61PP and GR70PP membranes are made of polysulphone with MWCO values ranging from 100,000 to 20,000.

- The GR80PP, GR90PP and GR95PP membranes are made of polyethersulphone with MWCO values ranging from 10,000 to 2,000.

Dairy UF-pHt™ types

The series of Alfa Laval flat sheet ultrafiltration membranes for the dairy industry covers the GR60PP, GR61PP, GR70PP, GR73PP and GR82PP membrane types.

- The GR60PP, GR61PP and GR70PP membranes are made of polysulphone with MWCO values of 20,000 and 10,000.

- The GR73PP and GR82PP membranes are made of polyethersulphone with MWCO values of 10,000 and 5,000.

Benefits

- cover a broad spectrum of flux properties, pore sizes, molecular weight cut-off values and rejection capabilities

- available by the metre, as standard 20 x 20 cm sheets or cut into flat sections to fit into all Alfa Laval plate-and-frame module configurations

- delivered with necessary lock and passage rings

- suitable for extensive range of processes

- manufactured by Alfa Laval's own membrane centre

Kako radi

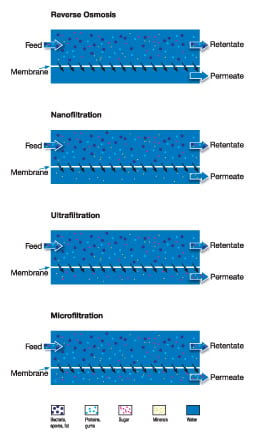

Reverse osmosis (RO)

RO uses the tightest possible membrane in liquid separation. In principle, water is the only material that can permeate the membrane. All other materials (salts, sugars, etc.) will be unable to pass through.

Nanofiltration (NF)

NF is not as fine a separation process as reverse osmosis, and uses membranes that are slightly more open. Nanofiltration allows small ions to pass through while excluding larger ions and most organic components.

Ultrafiltration (UF)

UF involves using membranes in which the pores are larger and the pressure is relatively low. Salts, sugars, organic acids and smaller peptides are allowed to pass, while proteins, fats and polysaccharides are not.

Microfiltration (MF)

In MF, suspended solids, bacteria and fat globules are normally the only substances not allowed to pass through.

Compliances

All materials used for the production of Alfa Laval membranes, in both spiral-wound and flat-sheet membrane designs and configurations, comply with EU Regulation (EC) 1935/2004, EU Regulation 10/2011, EU Regulation (EC) 2023/2006 and FDA regulations (CFR) Title 21. The membranes are thus suitable for use within food and pharmaceutical processing applications.

These compliance also extend to the equipment and fittings related to membrane operations, including items such as plate-and-frame units, element housings and pumps.