AQUA Blue

Alfa Laval AQUA Blue freshwater generators convert seawater into high-quality fresh water with an optimized process that occurs in a single plate pack. The AQUA plate technology cuts seawater flow needs in half compared to conventional freshwater generators, which reduces pumping needs, electrical power consumption and related CO2 emissions. A family of single-stage AQUA Blue solutions is available, offering different connection possibilities and covering capacity needs of 1–60 m3 per day.

Half the seawater flow, half the energy needed

- Half the seawater flow and pumping needs of other freshwater generators

- Thermally driven process requiring little electrical power

- Easy operation

- Reduced installation costs thanks to smaller piping

- Easy and efficient maintenance on site thanks to non-glued gaskets

With smaller piping and no outer shell, AQUA Blue freshwater generators perform vacuum distillation in a minimized space. The latest AQUA Blue E1 technology, which has non-glued gaskets, allows easy regasketing on site.

Three single-stage AQUA Blue versions are available, all producing high-quality fresh water while requiring almost no effort from the crew. The smallest in the family is the AQUA Blue Mini E1, optimized for capacities of 1–15 m3/day, which has a tiny footprint and weighs less than half as much as other AQUA Blue models. In addition, there is the two-stage AQUA Blue E2 freshwater generator, which provides additional capacity and savings opportunities.

AQUA story´s new chapter of energy efficiency

AQUA Blue a story of innovation

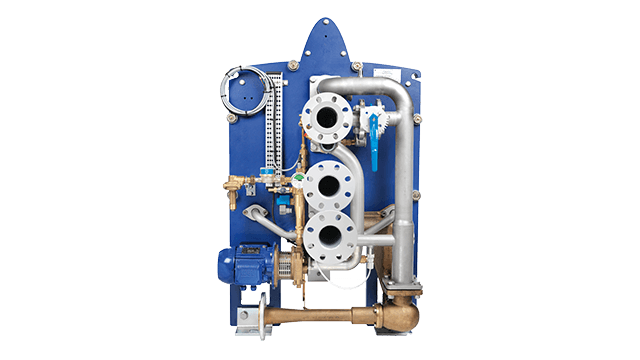

AQUA Blue E1 C-type

For capacities up 60 m3/day, the single-stage E1 C-type is the original AQUA Blue and a leading solution for producing fresh water on marine vessels. Besides offering major space savings, it cuts electrical power consumption by 50% over conventional freshwater generators. The system takes its feed water from the flow of seawater coolant.

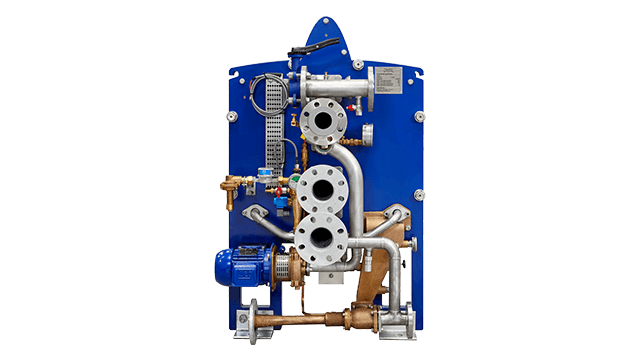

AQUA Blue E1 S-type

For capacities up to 60 m3/day, the AQUA Blue E1 S-type takes its feed water from the condenser outlet or an alternative source. It can thus make use of the existing seawater pumps on board. This cuts electrical power needs by 70% compared to conventional freshwater generators, and it reduces footprint by up 15% compared to the AQUA Blue E1 C-type.

AQUA Blue Mini E1

For capacities of 1–15 m3/day, the AQUA Blue Mini E1 makes the advantages of AQUA technology available to vessels that need less fresh water. Around half the size of other single-stage AQUA Blue models, it has a tiny footprint and needs very little electrical power. It offers a simpler, more reliable and more cost-effective alternative to reverse osmosis or bunkering fresh water.

Reliable production of high-quality fresh water

AQUA Blue freshwater generators provide a continuous supply of low-salinity (below 2 ppm) fresh water on board, which is more convenient and economical than bunkering water. Unlike reverse osmosis, which is electrically driven and becomes less efficient for every degree below 25°C, AQUA Blue freshwater generators are thermally driven and offer consistently high performance.

Easy operation and maintenance

AQUA Blue freshwater generators offer start-and-forget operation, with no filters to clog or sensitive membranes to break. Scaling and fouling are easily removed through occasional Cleaning-In-Place (CIP), without having to open the freshwater generator.

On rare occasions when the freshwater generator must be opened, e.g, for gasket replacement, the plate pack simply slides open within the frame – requiring no additional service area. Thanks to the unique non-glued gaskets, operators can easily perform regasketing on site, which means no transporting plates or bunkering extra water.

Advantages for shipyards

Shipowners and operators are not the only ones who benefit from AQUA Blue freshwater generators. Shipyards experience reduced installation work and costs, thanks to the use of smaller seawater pumps and the smaller dimensions of piping and valves. Since the compact design requires no additional service area, fewer accommodations are needed in the engine room.

AQUA Blue digital training

Explore and learn to operate AQUA Blue freshwater generators in a 3D-simulated environment.

Kako radi

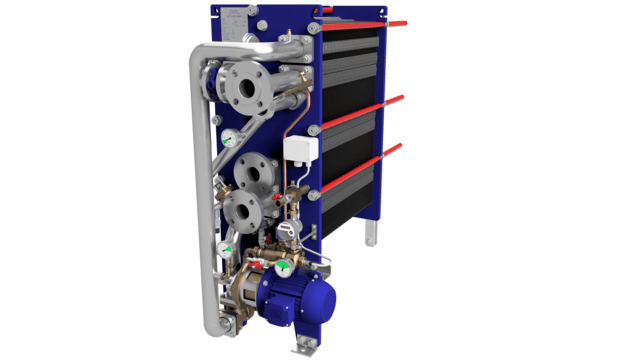

3-in-1 AQUA plate technology

AQUA Blue freshwater generators comprise a single type of titanium plate that handles all three aspects of vacuum distillation: evaporation, separation and condensation. Only the gasket configuration differs between the process and utility plates (see illustration). Because the process vacuum is contained within the plate pack itself, no outer shell is necessary.

The AQUA freshwater generation process

Feed water enters the lower (evaporator) section of the plate pack, where the plates are warmed by engine jacket cooling water or a closed circuit heated by steam. This causes the water to evaporate at around 40¬–65°C in a vacuum of 75–99%, which is maintained by the brine/air ejector. (The exact temperature and vacuum ranges depend on the AQUA Blue model.) For the AQUA Blue E1 C-type and S-type, a high-pressure option is available for jacket water pressures up to 6 bar.

The vapour produced through evaporation rises into the middle (separator) section of the plate pack, where any droplets of entrained seawater are removed. Gravity causes these droplets to fall back into the brine sump at the bottom of the freshwater generator.

Only clean freshwater vapour reaches the top (condenser) section of the plate pack, which is cooled by a flow of seawater. Here the vapour is condensed into fresh water, which is pumped out of the freshwater generator.

AQUA Blue E1 C-type connections

AQUA Blue E1 S-type connections