Astepo grande punjač

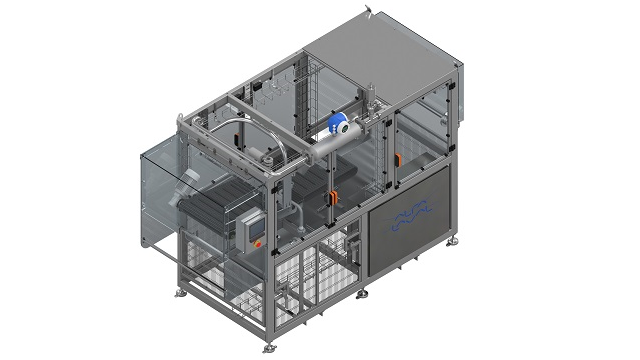

Increase your manufacturing facility’s production capacity and profitability with the Alfa Laval Astepo grande filler. Automated operation is straightforward. Adjustable bag loading and efficient changeover between bag sizes, closures and cleaning cycles boost uptime and increase output. Versatile, efficient and easy to maintain, this large non-aseptic bag-in-box filling machine easily adapts to bag size, cap type or packaging design while handling up to 700 bags per hour.

Decrease your production loss time and maximize uptime with our automatic bag-in-box filler

- Ensure production safety and extend shelf life by preventing oxygen pick-up during hot and cold fills

- Safeguard process hygiene with superior cleanability the filler interior and wash-down of the exterior

- Spend less time switching between the production phases and more time increasing output

- High yield due to less downtime between production and cleaning

- Global expertise with a truly local service and support network

Efficiently fill bags from 2–20 litres with the Alfa Laval Astepo grande filler. It minimizes downtime between production and cleaning-in-place (CIP). Used worldwide, this automatic liquid filling equipment transfers wine, beverages, thick sauces, post-mix products, syrups and vegetable oils and other shelf-stable products – safely, quickly and reliably.

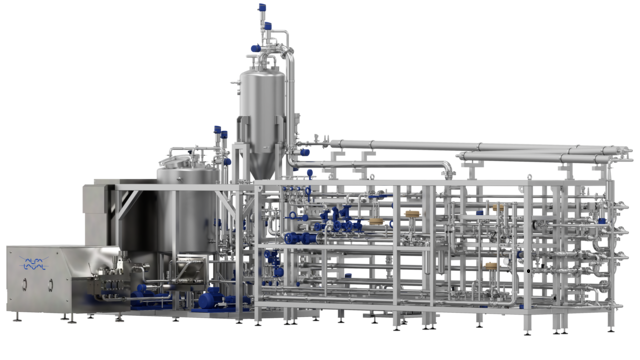

Special versions of production setups are available to meet various requirements for hygiene standards and add process flexibility – no matter the bag size, cap type or packaging design.

Count on the Astepo grande filler for maximum productivity and versatility. Higher filling speeds, easy operation and maintenance, and unmatched performance come together in the Astepo grande filler. Plus, it’s quick and easy to swap bag sizes and closures–from caps, spouts and dispenser taps.

How does the Alfa Laval Astepo grande filler work?

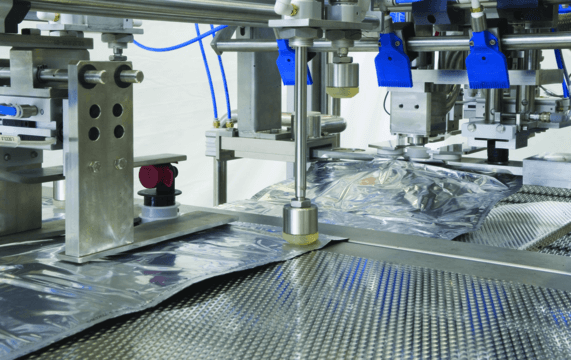

The Astepo grande filler system uncaps, fills and caps bags with capacities of 2–20 litres, with a filling accuracy of ±0.5%. Input capacities are up to 700 bags per hour, depending on the bag size selected. The system uses web bags with front-mounted caps. A soft horizontal knife protects the film from micro-perforation and separates the bags. A pneumatic system automatically feeds the bags to the filling head.

A pneumatic cylinder synchronizes with the cap removal clamps with the filling valve to ensure rapid changeover and easy adjustment. Fitting an optional mass flow meter helps ensure extremely accurate filling.

Special configurations are available with a pre-filling vacuum, a post-filling nitrogen puff, or a HEPA filter over the filling area.