Packinox+

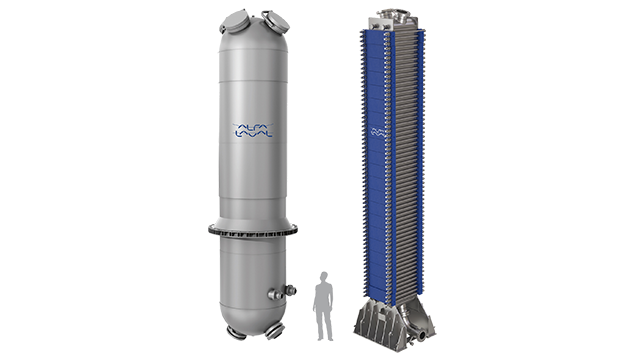

The Packinox+ combines high temperature and pressure resistance with exceptional thermal performances, while reaching low pressure drop. It is a compact solution for maximal energy recovery in positions with high flowrates, temperatures and pressures. A single Packinox+ offers higher capacity than systems comprising several large shell-and-tube heat exchangers, resulting in significantly lower CAPEX and OPEX.

Robust performance

Combining high temperature and pressure resistance with exceptional thermal and hydraulic performance, Alfa Laval Packinox+ is a compact solution for maximal energy recovery in positions with high flowrates, temperatures, and pressures.

The Packinox design is well proven and there are more than 500 units in operation in plants across the world. The high performance, high reliability and short payback time has made Packinox the industry standard in energy-intensive applications such as catalytic reforming and aromatics production.

- Outstanding heat transfer efficiency, enabling large energy savings and cuts in CO2 emissions

- Robust design brings reliable uptime – even in the toughest applications

- Perfect for heat recovery duties with very long temperature programmes

- Ideal for asymmetric flows thanks to FlexFlow technology

- Low CAPEX and short payback time

Webinar

Improving performance with Packinox+

Watch the webinar to find out how Alfa Laval Packinox+ heat exchangers can help improve the performance of your large-scale industrial heat recovery processes. You will also learn more about our new FlexFlow technology.

- Cut costs

- Boost efficiency

- Slash carbon footprint

- Lower CAPEX

Configurations and capabilities

Packinox+ is available as plate-and-shell configuration and plate-and-frame configuration. A single Packinox+ heat exchanger offers the same heat transfer capacity as multiple shell-and-tube heat exchangers with an equivalent heat transfer area of up to 35,000 m2.

How it works

A Packinox+ combines high-pressure durability with superior thermal performance.

Watch the animation and download technical data sheets to find out more about the working principle and design of a Packinox+ heat exchanger, and the differences between the plate-and-shell and plate-and-frame models.

References

We have been working with companies all over the world, in various industries, to help them maximize flexibility, reliability, and yield.

Read more about how Alfa Laval’s Packinox heat exchangers, agile project management, and expert technical support have made us these customers’ first choice.

Meet our experts

Listen to our heat exchanger experts as they share their expert knowledge about how you can maximize heat transfer in your processes.

They will cover a range of topics, ranging from long duration energy storage to asymmetric flows for all kinds of applications.

Sustainability

Investing in an Alfa Laval Packinox+ heat exchanger gives a high return on investment, and there are numerous ways a Packinox+ can help improve both your bottom line and your environmental profile:

• Reduced CAPEX

• Lower OPEX

• Increased production

• Lower CO2 emissions

Documents

Downloads

Product leaflet

Product brochures

Case stories

Press release

Service from A to Z

Our team of service experts is ready to support you throughout the entire lifetime of your Packinox+ heat exchanger with every step from planning to execution.

We offer a complete range of on-site and remote services that ensure maximum operational reliability, great performance, and high total return on investment.

In this video you will see how we ensure performance over time.

Find out more about our service offerings for Packinox heat exchangers

Related industries

Unique features

Alfa Laval Energy news on Linkedin

Learn how our solutions, and the support we can offer, can help you identify new possibilities for both profitable growth and a positive environmental impact. On our showcase page you can keep up to date with our latest innovations and solutions and the work we do within clean energy, energy efficiency, and the circular economy.