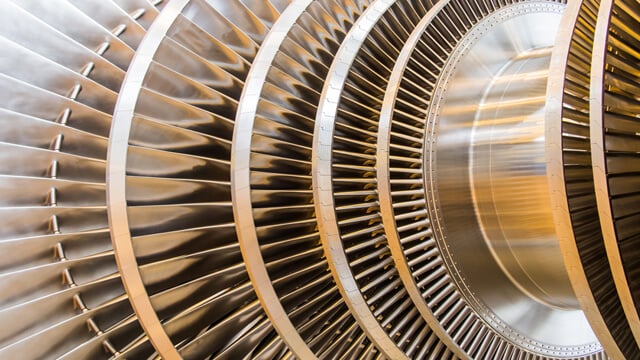

Kondenzacija parne turbine

To improve plant economics , high thermal efficiency, minimal footprint and low maintenance are essential requirements for efficient cooling of exhaust steam from the turbine. With vast expertise in supply the power industry, Alfa Laval offers a broad portfolio of compact and reliable condensers for use in converting exhaust steam into condensate.

On the pulse of steam turbine condenser cooling

Whether condensing exhaust steam from the turbine by means of water or directly with air to subatmospheric pressure, Alfa Laval has a broad portfolio of condensers to do the job – from semi-welded plate type condensers, fully welded to wet surface air coolers. Power plant owners and operators rely on our range of equipment for use in exhaust steam condensation processes as main condensers for plants with capacities of up to 20 MW as well as dump condensers or other types of auxiliary condensers.

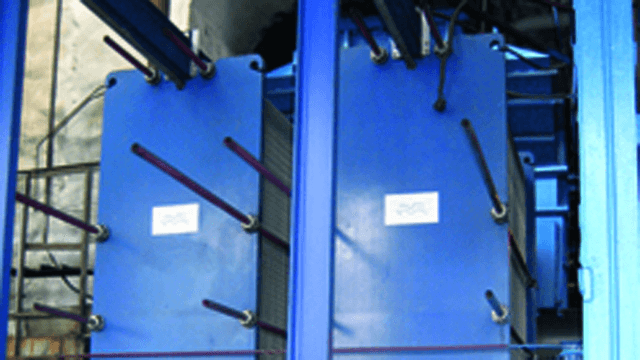

Main condenser

Tailor-made to condense steam at subatmospheric pressures, the AlfaCond is a semi-welded plate heat exchanger capable of handling condensation duties up to 20 MW. This makes it the perfect choice as main condenser for smaller power plants. It features a highly efficient roller-coaster plate pattern, unique distribution of inlets for the steam and cooling water as well as removal of inerts on the outlets.

The AlfaCond can be supplied individually as a stand-alone heat exchanger or as a part of a complete condenser system: The AlfaCond Module. The AlfaCond Module is a standardized system designed for condensing vacuum steam from steam turbines and other steam-consuming equipment used in the power industry. A complete, integrated system, the module is pre-configured with all the subsystems and components required to ensure efficient, reliable steam condensation under the rated design conditions. The core of this modular system is the AlfaCond plate surface condenser, which is designed for highly efficient vacuum-vapour condensation.

The unique design of the AlfaCond condenser results in substantially higher thermal efficiency than conventional shell-and-tube heat exchangers. Therefore a much smaller heat transfer area is required, making the condenser extremely economical to operate.

Wet surface air coolers

Alfa Laval Wet Surface Air Coolers (WSAC®) are efficient closed-loop, evaporative cooling systems for heavy-industry vapor condensation duties. Alfa Laval works closely with power plant owners and operators to design highly reliable, compact and efficient steam turbine condensation processes using our packaged, custom or modular systems.