Paper mill

Dewatering diluted stock into paper requires vast amounts of mechanical and thermal energy. Designed for paper mill applications from deaeration to coating, Alfa Laval’s gasketed heat transfer, separation and fluid handling technologies maximize reliability, increase heat recovery, reduce costs and boost productivity.

Increasing production efficiency

at the mill

Every paper mill is unique, but the challenges that mill operators face are many. Mill operators must find ways to remain profitable despite increasing labour, pulp and energy costs while maintaining mill productivity and product quality.

Getting the most out of raw materials using less energy and water while maintaining end-product characteristics requires process knowledge as well as the right technologies, equipment and services to extend performance. Alfa Laval understands what it takes to achieve all this throughout mill.

Improving energy efficiency

Energy accounts for up to 30 percent of the mill production costs. So it comes as no surprise that energy-intensive mills must focus on energy efficiency. Alfa Laval offers a broad range of solutions to optimize the use of energy at paper mills. These improve quality, productivity and reliability while delivering savings to the bottom line.

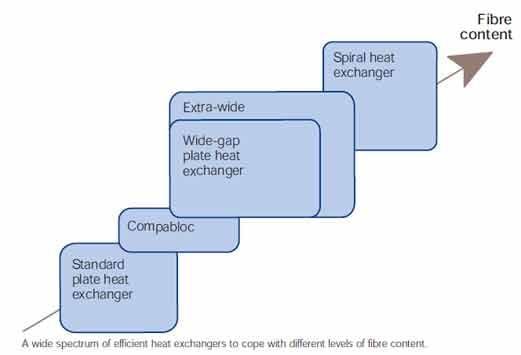

Easy handling of fibrous process fluids

Fibrous fluids at your mill? No problem. It doesn’t matter that one or both of the process fluids contain fibres and other solids. Alfa Laval heat transfer, separation and fluids handling equipment handles process fluids containing fibres and other solids with ease while providing high thermal efficiency and maximum heat recovery. Other benefits include low installation, operation and maintenance costs as well as complete access to both sides of the plates to ensure easy yet thorough cleaning, should this prove necessary.

Higher productivity through efficient drying

Steam and condensate systems are critical in maximizing productivity and minimizing energy consumption. Compact, efficient and highly reliable, Alfa Laval heat exchangers are widely used throughout these systems. To meet your requirements for these high-temperature and/or high-pressure applications, Alfa Laval provides a wide range of heavy-duty heat exchangers, including gasketed, semi-welded and fully welded designs.

Efficient wastewater treatment

Processing large volumes of wastewater and residual sludge waste poses challenges for many mills. Alfa Laval offers a complete spectrum of wastewater equipment that helps minimize environmental impact and maximize energy savings. Water line applications include MBR, SBR, heat exchangers and tertiary filtration using membranes or cloth media. For sludge line applications, Alfa Laval offers a full range of equipment for thickening and dewatering.

Download

Grow your pulp mill profits with more efficient separation

Alfa Laval offers pulp mills a wide range of solutions for extraction of by-products and recovery of process chemicals. Our separation equipment brings you benefits such as high yield, high product quality, low operating costs and compact installations.

Learn how Alfa Laval's separation solutions can improve your bottom line

Boost profits - recycle your energy

Investments in waste heat recovery are often very profitable. Payback periods are typically less than a year.

Industrial water and waste treatment

Alfa Laval offers a variety of solutions for on-site water and waste treatment plus recovery of water, heat and also products from your process.

Learn more about our Industrial water and waste treatment solutions