Batch olive oil production

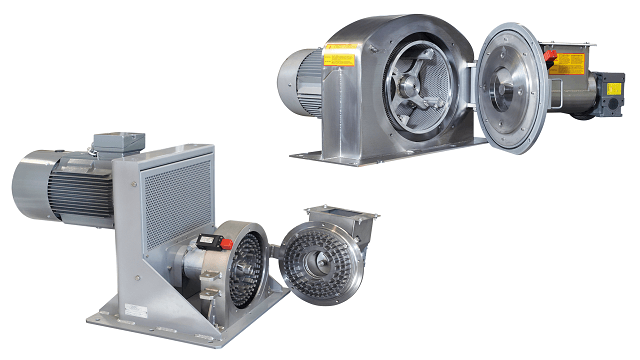

Alfa Laval offers a wide range of equipment designed for meeting the unique challenges of batch and small-scale continuous olive oil production. Our flexible technology makes it easier to process different batches of locally sourced olives with widely varying specifications, with the control to fine-tune your processes according to your customers’ demands. They also ensure you have proven solutions for efficiently and reliably handling short, busy harvests.

Flexibility and dependability to master small-scale production

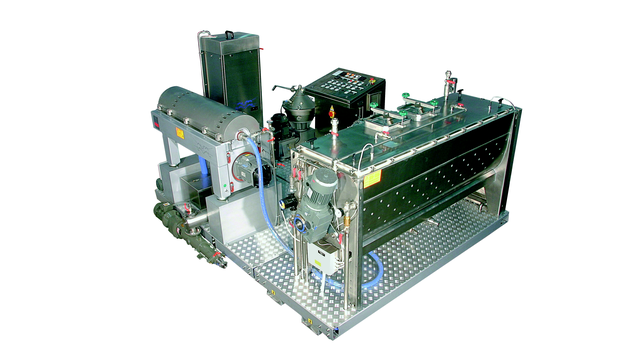

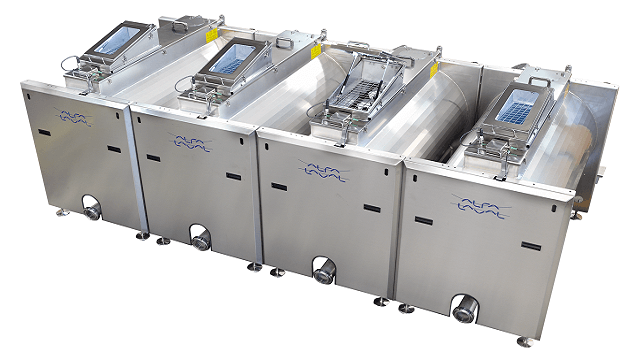

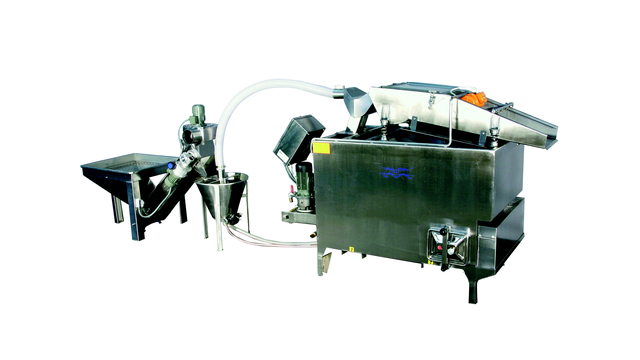

No matter the size of your mill or if you’re focused on batch or small-scale continuous production, Alfa Laval can support you with both cutting-edge technology and an unrivalled level of expertise. Designed with knowledge gained from more than 80 years of experience in the industry, our portfolio includes flexible solutions that allow you to independently manage your production. From our easily scalable batch malaxer to the complete and compact AlfaOliver 500 continuous extraction line, our full range of equipment is easily adaptable to meet production increases and decreases as well as shifting tastes of your consumers.

Achieve artisan quality from every batch

- Proven technology that puts industrial-level productivity and reliability into the hands of artisan olive oil mills

- Versatility to handle olives that vary considerably in type, volume and quality

- Compact equipment for lines that are easy to install in mills with limited space availabilities

- An experienced partner with the expertise to help you achieve the quality product your consumers crave

- Process control that allows for flexibility to adjust to harvest circumstances or market changes

Srodni proizvodi

Support you can count on – no matter where you are

When you partner with Alfa Laval, the equipment is just the beginning. With a truly global service network, we can be there at your side no matter where your mill is located. We are here for you throughout the entire lifecycle of your equipment, with support for installation and start-up, ongoing routine maintenance and monitoring, and even suggestions for continuous process improvements.