2024-09-30 Product news

Alfa Laval scales up the use of low-CO2-emission steel as part of the Concept Zero™ initiative

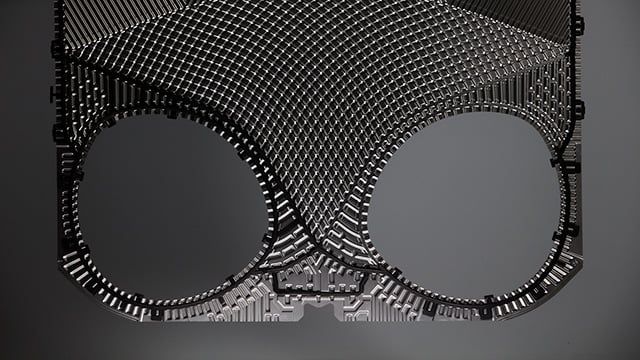

Alfa Laval is now ramping up the use of low-CO2-emission steel in its world-leading plate heat exchangers. Alfa Laval was the world’s first manufacturer to introduce low-emission steel in its plate heat exchangers already in 2022. Now the company is expanding the use of low emission steel to one of its most sold products – The T21 plate heat exchanger.

Scaling up production

From this autumn, T21 gasketed plate heat exchangers from Alfa Laval’s manufacturing facility in Lund, Sweden will be made using SSAB Zero™ steel in the heat exchanger frames. Handling duties up to 10 bar design pressure in a wide range of industries and applications, ranging from clean hydrogen production and HVAC to heavy industry. By using SSAB Zero™ in the frames, these unique heat exchangers are produced with up to 39% less CO2 emissions.

In our carbon neutrality journey, Alfa Laval is already implementing the solutions available to reduce Scope 1 and 2 emissions towards net zero. The reduction of Scope 3 upstream emissions is harder and requires both innovation and collaboration. In our journey, the collaboration with SSAB is an important step as steel is one of the main materials in heat exchangers. Alfa Laval is proud to lead the way in the industry when it comes to sustainable material in our plate heat exchangers and we are putting a lot of efforts into exchanging also other components in our products to low emission alternatives. says Julien Gennetier, President Business Unit Gasketed Plate Heat Exchangers, Alfa Laval.

The new steel is produced by the Swedish steel company SSAB and called SSAB Zero™. It is made from recycled steel and produced using fossil-free electricity and biogas - resulting in steel produced with virtually no fossil carbon emissions.

For further information, please contact:

Kajsa Dahlberg

Sustainability, Alfa Laval

Mobile: +46725731689

E-mail: kajsa.dahlberg@alfalaval.com

Oliver Hellberg

Marketing, Alfa Laval

Mobile: +46730434478

E-mail: oliver.hellberg@alfalaval.com

This is Alfa Laval

The ability to make the most of what we have is more important than ever. Together with our customers, we’re innovating the industries that society depends on creating positive impact. We’re set on helping billions of people to get the energy, food, and clean water they need. And, at the same time, we’re decarbonising the marine fleet that’s the backbone of global trade.

We pioneer technologies and solutions that free our customers to unlock the true potential of resources. As our customers’ businesses grow stronger, the goal of a truly sustainable world edges closer. The company is committed to optimizing processes, creating responsible growth, and driving progress to support customers in achieving their business goals and sustainability targets. Together, we’re pioneering positive impact.

Alfa Laval was founded 140 years ago, has customers in some 100 countries, employs more than 21,300 people, and annual sales in 2023 were SEK 63.6 billion (5.5 BEUR). The company is listed on Nasdaq Stockholm.

Oznake

Sve

About Concept Zero

Concept Zero is Alfa Laval’s vision and target to produce the world’s first carbon neutral heat exchanger by 2030. It will be a heat exchanger using low CO2 emission materials. Additionally, the heat exchanger is prepared to easily be recycled. Click to know more about Concept Zero.

About SSAB Zero™ steel:

SSAB Zero™ steel is produced with near zero fossil carbon emissions (less than 0.05 kg CO2 emissions per kg steel in Scope 1 and 2). SSAB practices market-based emission factors for the electricity used and may secure fossil-free electricity through guarantees of origin. Recycled steel is used as a raw material, which means SSAB Zero™ supports the circular economy.