Foodec

Alfa Laval Foodec decanter centrifuges are ideal for industries where delicate food and beverage products are processed – and where easy cleaning is crucial.

Centrifugal separator with unparalleled efficiency and easy cleaning

- Efficient liquid extraction ensures high yield and low moisture in the discharged solids

- All product wetted components easy to clean thanks to well positioned CIP nozzles and an efficient CIP sequence at low speed tumbling

How does the Foodec decanter centrifuge work

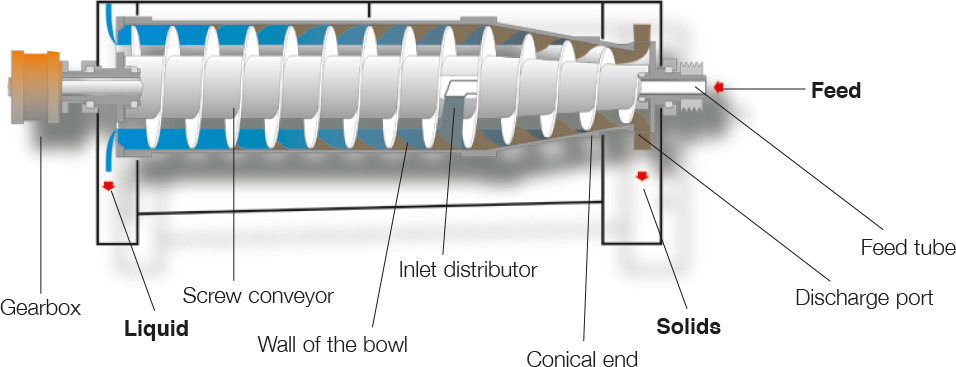

Separation takes place in a horizontal cylindrical bowl equipped with a screw conveyor. A stationary inlet tube introduces the product into the bowl, and a distributor gradually accelerates it. Centrifugal forces separate solids from the liquid. The solids are collected and compacted on the bowl wall.

A conveyor rotates inside the bowl at a slightly different speed. This transports the settled solids on the bowl wall towards the conical end. Foodec's design increases hydraulic pressure inside the drum to improve flow through a narrow opening. The compacted and dewatered solids leave the bowl via discharge openings at the smaller diameter of the conical end. Separation takes place in the entire length of the cylindrical part of the bowl, and the clarified liquid leaves through a paring disc (internal centripetal pump).

All wetted parts in Foodec decanter centrifuges for the food industry are made with stainless steel. The control system is equipped with a graphic user interface and multiple communication options.