AlfaFlash

The Alfa Laval AlfaFlash plate flash evaporator concentrates high-viscosity, high-fouling and shear-thinning fluids, safely, reliably, effectively. Compact, self-cleaning and easy to maintain, this forced circulation plate evaporator handles process liquids with high levels of suspended solids, meeting medium to zero liquid discharge requirements. Suitable for applications – from proteins, food, beverage, starch, and sweeteners to life science and industrial fermentation to wastewater.

Concentrate high viscosity, fouling-prone and shear-thinning fluids with ease

- Maximum uptime due to minimal fouling as a result of a higher shear rate and higher turbulence, which creates a self-cleaning effect

- Minimized disposal and transport costs due to highly efficient concentration of high-viscosity or shear-thinning process liquids

- Compact, space-saving footprint due to reduced height and weight compared to shell-and-tubes, cutting installation, operating and maintenance costs

- Excellent preconcentration and turndown capabilities due to energy-efficient dryers and adjustments to varying feed composition during recirculation

- Perfect for boosting capacity and debottlenecking existing evaporation systems

Versatile, compact, and self-cleaning, the Alfa Laval plate flash evaporator is effective for a broad range of applications with high viscosity, fouling-prone process liquids with high-solids content, such as supersaturated salt solution and olive mill effluent. Perfect for new or retrofit installations, these evaporators meet medium- to zero-liquid discharge requirements across all industries.

- BlueVap – a fully automated, pre-assembled thermal separation system that concentrates olive mill black water into 80% clear water and 20% biodegradable cake. No steam or cooling water required.

- AlfaFlash – a forced circulation evaporator that concentrates challenging process liquids with suspended solids and some crystallization

It’s a hundred times better than the old system! Apart from a scheduled summer close-down, it has run without interruption, producing the quality and consistency of Pot Ale we want. We clean the units in place by flushing at the end of each week and when we inspected the heat transfer surfaces during the summer shut-down, they were clean as a whistle.” – Shane Fraser, Distillery Production Manager, Glenfarclas Distillery

Alfa Laval helps us reach our goal of a zero-waste olive oil production with BlueVap.’ –Owner, Frantoio di Santa Téa, Reggello, Italy

Perfect for non-Newtonian fluids

Due to the corrugated plate pattern which promotes turbulence and continuous cleaning, the AlfaFlash flash evaporator does not foul as rapidly as shell-and-tube flash evaporators. In addition, when a product is shear thinning (stillage, corn steep liquor, protein solutions, etc.), the high shear of AlfaFlash flash plate evaporator reduces the apparent viscosity of the process liquid, which further reduces fouling and improves heat transfer performance.

U poređenju sa tradicionalnim sistemom za isparavanje cev-u-cevii, AlfaFlash i AlfaVap sistem zahtevaju znatno manju visinu ugradnje i mogu se instalirati bez složenih građevinskih radova na lokaciji.

Izvori toplote za sisteme isparavanja

Podešavanje opcija

Alfa Laval sistemi za isparavanje mogu da koriste toplotu iz različitih izvora kao što su mehanička i toplotna kompresija, kao i otpadne pare iz sušara.

Sistem sa više efekata

- Štedi energiju ponovnom upotrebom pare

- Jednostavno i fleksibilno

Mehanička rekompresija pare, MVR

- Visoka investicija

- Mala (ili nikakva) potrošnja pare

- Koristi električnu energiju

Termička rekompresija pare, TVR

- Mali troškovi sa smanjenom potrošnjom pare

- Jednostavno, bez pokretnih delova

Otpadna toplota iz sušara

- Niski troškovi energije

- Relativno visoka investicija

Pilot testiranje i iznajmljivanje sistema za isparavanje

Isprobaj pre kupovine. Dobijte stručnost i savete od inženjera kompanije Alfa Laval za optimalnu konfiguraciju vašeg sistema za isparavanje, uključujući:

- Detaljna analiza i karakterizacija vode

- Modeliranje hemije procesa i vode

- Referentna vrednost i/ili pilot testiranje za primene umerenog do visokog rizika

- Detaljna procena kompatibilnosti materijala

- Analiza uzorka

- Pilot testovi

Posetite Alfa Laval laboratoriju za tehnologiju i hemiju materijala i test centar u Lundu, Švedska, Alfa Laval centar za inovacije i testiranje u Nakskovu, Danska, ili iznajmite jedan od naših mobilnih pilot sistema za isparavanje kako biste sproveli ispitivanja na licu mesta u vašoj fabrici.

Proizvodi

Usluge

Usluge za prehrambene sisteme

Usluge Alfa Laval za prehrambene sisteme pomažu u poboljšanju učinka vaših prehrambenih sistema maksimiziranjem učinka vaših procesa. Ovo vam omogućava:

- Da neprestano poboljšavate svoje poslovanje kako biste održali konkurentsku prednost

- Da se fokusirate na vreme rada bez kvarova, optimizaciju i dostupnost

- Da maksimalno povećate povraćaj ulaganja tokom životnog ciklusa vaših prehrambenih sistema

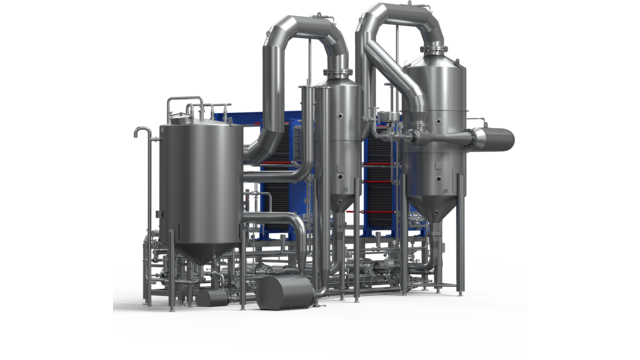

Projektovani sistem

Kompletan sistem AlfaVap isparivača za film u usponu uključuje pločaste isparivače, predgrejače, posude za separaciju ciklona, termičke i/ili mehaničke jedinice za rekompresiju pare, pumpe, instrumente, ventile, kanale i cevovode i lokalni programabilni logički kontroler (PLC) i kontrolnu tablu. Sistem se može unapred montirati u radionici kompanije Alfa Laval, što smanjuje vreme instalacije na lokaciji na jednu do tri nedelje.

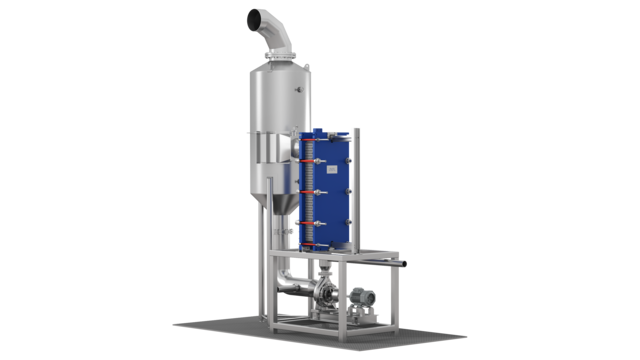

How a plate flash evaporator works

The Alfa Laval AlfaFlash plate flash type evaporator is a forced circulation flash evaporator. A pump recirculates the liquid between the cyclone separator vessel and the plate flash evaporator creating a highly turbulent flow inside the plate heat exchanger.

Boiling does not take place in the plate heat exchanger but rather the liquid is heated under pressure. The actual evaporation takes place when the heated liquid is discharged to the separator vessel where the pressure is released and the volatile liquid then flashes. Many AlfaFlash applications run under vacuum.

Multi-effect designs reduce the steam consumption requirements: the vapour produced in one effect is used as the heating media in a subsequent effect. In combination with thermal vapour recompression (TVR) and/or mechanical vapour recompression (MVR), the steam consumption can be reduced to a fraction of the evaporation capacity.

A complete AlfaFlash system includes the plate evaporators, preheaters, separator vessels, TVR or MVR, recirculation pumps, instruments, valves, ducting, piping, and a control panel.

Takođe biste mogli biti zainteresovani za...

Rešenja za isparavanje 3D/VR

Krenite u obilazak naših sistema za isparavanje od 360 stepeni izbliza. Pogledajte 3D/VR modele sistema za isparavanje jednostavnim klikom na jedan od modula.

Istražite naš asortiman isparivača

Alfa Laval nudi širok spektar sistema za isparavanje od pločastih isparivača i isparivača sa uspinjućim filmom do cevastih isparivača i isparivača sa padajućim filmom. Saznajte šta bi odgovaralo vašim potrebama za isparavanjem.