Fuel oil filters

Moatti fuel oil filters build on the innovative Alfa Laval Atrium 2.0 technology for automatic self-cleaning filters. Available in several sizes and configurations, they handle fuel oil for all four-stroke and two-stroke engines, whether they are running HFO, MDO/MGO or biofuels. Highly compact with no compromise on filtering area, the provide high efficiency fine filtration with virtually no pressure drop for optimal protection against catalytic fines.

Compact engine protection

- Easy installation

- Minimal pressure drop across the filter

- Low and predictable maintenance

Biofuel-ready

Moatti fuel oil filters are suitable for use with biofuels of the following type:

- Fatty Acid Methyl Esters (FAME), compliant with EN 14214

- Hydrotreated Vegetable Oils (HVO)

- Blends of the above with ISO 8217–compliant hydrocarbon fuels

Products

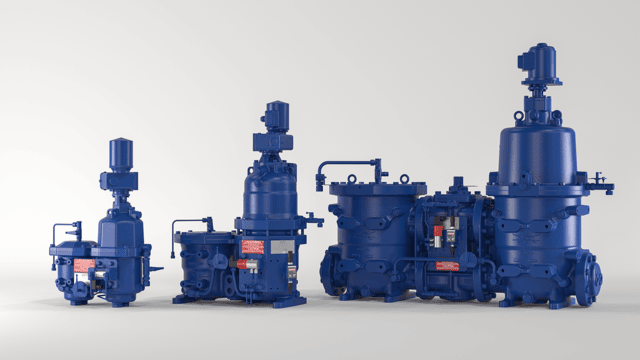

Moatti 152 filters

With high-efficiency fuel oil filtration for four stroke or small two stroke engines – the 152 filter is a proven filter solution, protecting your engine from catalytic fines and fuel instability

Moatti 180 filters

Our most compact system yet, the 180 filters don’t compromise on filtering area while still delivering high efficiency fine filtration with virtually no pressure drop.

Moatti 290 filter

Alfa Laval Moatti 290 filters utilize the original Atrium technology for automatic self-cleaning filters. Our most modular range, the 290 filters will adapt to meet your requirements with precision.

Fuel oil filters

The F type range of Alfa Laval automatic fuel oil filter systems provides effective full-flow filtration of fuel oil (FO), heavy fuel oil (HFO) and marine diesel oils (MDO) up to 700 cSt/50°C. These fuels are widely used in modern two-stroke and four-stroke diesel engines, and the quality and cleanliness of such fuel has an important influence on engine efficiency, fuel consumption, reliability and service life.

This range of automatic fuel oil filter systems only requires very limited investment yet helps ensure reliable engine operation, along with peace of mind for those dependent on the engine working as intended. The robust, space-saving design makes these units easy to install as well as to retrofit as upgrades to existing installations.

These units use fuel oil that has already been filtered to backflush the filters, doing away with any need for a compressed air supply. This backflushed oil is then cleaned by refiltration in a special filter-equipped diversion chamber (which also uses the same backflushing principle) before being recirculated into the system. This diversion chamber acts as an automatic maintenance-free sludge treatment system, collecting and concentrating the particles backflushed from the full-flow chamber and the subsequent cleaning process into a concentrate sludge.

This means there is no need for a sludge treatment unit involving either manual cleaning or consumables that need replacing. Installation is recommended on the circulation side (hot loop) of the fuel oil system for maximum engine protection. Eliminating the use of colder backflush media prevents thermal shocks that can result in the formation of asphaltenes in the fuel. Options are available for additional features, such as a drain valve with an automatic timer, and a built-in changeover valve with bypass filter, enabling operations to continue uninterrupted during routine maintenance.

Kako radi

Osnovni princip iza Alfa Laval automatskih sistema za filtriranje lož ulja je pumpanje ulja kroz filter ka motoru – nakon prvog prolaska kroz sito koje uklanja sve krupnije neželjene materije koje mogu biti prisutne u sistemu – zaostale nakon održavanja, na primer.

Elementi za filtriranje punog protoka

Razdelnik, koga pokreće električni motor na vrhu kućišta filtera, zatim potiskuje lož ulje kroz niz elemenata za filtriranje punog protoka. Svaki element za filtriranje se sastoji od filterskog rama i filterskog sita, i podeljen je na delove u vidu rebara. Pojedinačni filterski elementi se povezuju u vidu niza filterskih diskova, gde delovi formiraju osam nezavisnih stubova za filtriranje punog protoka.

Razdelnik se redovno rotira, puneći sedam od osam stubova za filtriranje punog protoka. Čvrste materije se sakupljaju na površini filtera a filtrirano ulje nastavlja dalje ka motoru.

The distributor rotates on a regular basis, filling seven of the eight full-flow filtering columns. Solids collect on the filter surface and the filtered oil flows to the engine.

Povratno ispiranje čvrstih materija

U osmom stubu, čvrste materije koje su prikljupljene se izbacuju povratnim ispiranjem male količine filtriranog ulja kroz prolaz u razdelniku do komore za preusmeravanje. To znači da se svi filterski stubovi povratno ispiraju kada god razdelnik okrene pun krug – što obično traje do dva minuta.

Ulje koje je prošlo kroz povrano ispiranje, koje sada sadrži filtrirane čvrste materije, zatim ulazi u komoru za preusmeravanje i prolazi kroz sedam od osam filterskih stubova pre nego što se odvedu u deaerator (na takozvanoj „vrućoj strani“ sistema) ili u usisnu stranu dovodne pumpe (na „hladnoj strani“ sistema). Istovremeno, povratno ispiranje čistim uljem se obavlja u osmom stubu a čvrste čestice uklonjene na taj način se talože na dnu komore za preusmeravanje, odakle se periodično prazne kroz odvodni otvor.

Indikator pada pritiska se ugrađuje između dovoda i odvoda iz komore za pun protok, oglašavajući signal upozorenja ukoliko pad pritiska dostigne opasan nivo.

Proces automatskog povratnog ispiranja se pokreće malom razlikom u pritisku između odvoda čistog ulja i odvoda povratno-ispiranog ulja iz filtera.